# I am the Watcher. I am your guide through this vast new twtiverse.

#

# Usage:

# https://watcher.sour.is/api/plain/users View list of users and latest twt date.

# https://watcher.sour.is/api/plain/twt View all twts.

# https://watcher.sour.is/api/plain/mentions?uri=:uri View all mentions for uri.

# https://watcher.sour.is/api/plain/conv/:hash View all twts for a conversation subject.

#

# Options:

# uri Filter to show a specific users twts.

# offset Start index for quey.

# limit Count of items to return (going back in time).

#

# twt range = 1 422

# self = https://watcher.sour.is?uri=https://twtxt.net/user/https://twtxt.net/user/off_grid_living/twtxt.txt/twtxt.txt&offset=422

# prev = https://watcher.sour.is?uri=https://twtxt.net/user/https://twtxt.net/user/off_grid_living/twtxt.txt/twtxt.txt&offset=322

The plate will need covering in tape to ensure oxidation and rust does not get into copper plate. As well as protect humans from potential electrical shocks.

It was cheaper to purchase a 22mm drill bit than to get a business to drill further holes.

The copper rail bar, drilled to share the two battery posts, and nine 10mm brass bolts for adding power in or out.

@prologic Arhh, yes, but people chat more when they disagree than when they agree. So often being a programmed antagonist, actually is helpful.

@prologic wow, the Skinners Box is really taking over the world, and I can't stand it, you sit around at Smokeo watching people socially conditioned on their giant Skinner's Boxes, watching crap and not talking with you about normal things we used to do. And you don't need to be alert to the program, make the Facebook sensors do it all for you.

The copper rail bar, drilled to share the two battery posts, and nine 10mm brass bolts for adding power in or out.

@prologic Arhh, yes, but people chat more when they disagree than when they agree. So often being a programmed antagonist, actually is helpful.

@prologic wow, the Skinners Box is really taking over the world, and I can't stand it, you sit around at Smokeo watching people socially conditioned on their giant Skinner's Boxes, watching crap and not talking with you about normal things we used to do. And you don't need to be alert to the program, make the Facebook sensors do it all for you.

A rough, unpainted steel supporting frame for all the 18 battery cable wires leading from copper rail plate, pictured in orange, to the black wall. One wire shown in red.

Have any of you heard of the Denmark protest for 9 days over a bill of law forcing all to receive a mandatory vaccine. The people protested with pots and pans for 9 days and they dropped the bill.\nNow Western Australian Government has passed a similar bill of law, forcing people to become completely naked including removing underwear to receive a vaccine against their will. The people are protesting. They need the pots and pans and our support. All over a common cold virus, a strain which doesn't exist, according to a USA doctor and 7 others suing the FDA for evil.

A rough, unpainted steel supporting frame for all the 18 battery cable wires leading from copper rail plate, pictured in orange, to the black wall. One wire shown in red.

Have any of you heard of the Denmark protest for 9 days over a bill of law forcing all to receive a mandatory vaccine. The people protested with pots and pans for 9 days and they dropped the bill.\nNow Western Australian Government has passed a similar bill of law, forcing people to become completely naked including removing underwear to receive a vaccine against their will. The people are protesting. They need the pots and pans and our support. All over a common cold virus, a strain which doesn't exist, according to a USA doctor and 7 others suing the FDA for evil.

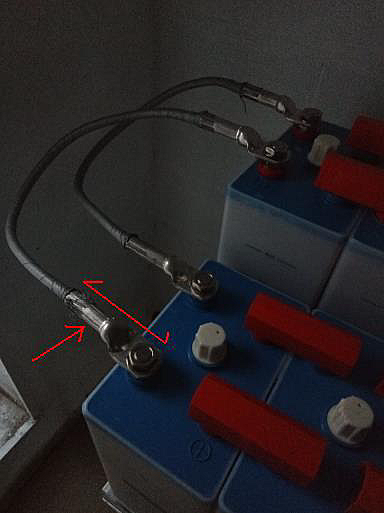

A closer view showing the original lug, and the processed crimped lug.

Red arrows show the lug 130mm long and it was 30mm wide now shrunk to 20mm wide.

A closer view showing the original lug, and the processed crimped lug.

Red arrows show the lug 130mm long and it was 30mm wide now shrunk to 20mm wide.

Finally the crimping company I found "Pirtek" in Blackwater was able to crimp these lugs, for just $22 using a machine able to crimp up to 30,000 tonnes of force, makes my crimping tool of 12 tonnes silly

@prologic_blog Interesting article, Spyda.dev only lacks the time, to become big enough to tackle Google as a search engine. And as you write, your backbone will not allow more crawlers adding to the engine database.

Finally the crimping company I found "Pirtek" in Blackwater was able to crimp these lugs, for just $22 using a machine able to crimp up to 30,000 tonnes of force, makes my crimping tool of 12 tonnes silly

@prologic_blog Interesting article, Spyda.dev only lacks the time, to become big enough to tackle Google as a search engine. And as you write, your backbone will not allow more crawlers adding to the engine database.

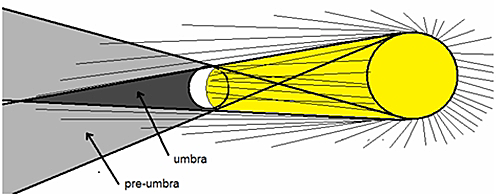

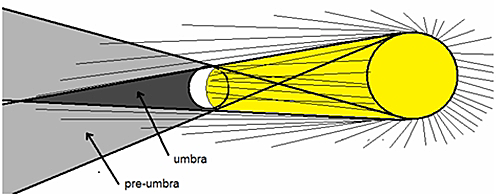

Light experiments

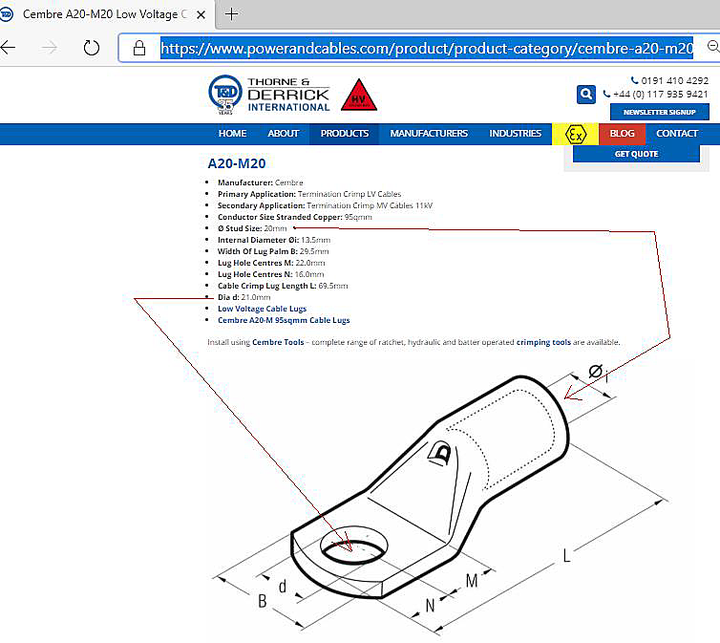

@lyse You so go to have around Lyse. I going to see if a local Engineer has a 20mm bit and drill these holes straight away, otherwise, I will have to drill it myself as you say. Who would know the most important hole is called the fixing hole and the least important hole is called the stud hole. Stupid terminology, nothing is every explained/

True better to engineer things yourself, anyhow, I have to drill out these holes bigger, just because of the confusion of words over products. \n\nWhat happened to keep is simple stupid. KISS

Quote "While it is in the family of coronaviruses, COVID-19 is a new virus affecting humans"\n\nThe word "it" refers to the common cold virus.\n\nWhile"common cold virus" is in the family of coronaviruses, COVID-19 is a new virus affecting humans.\nReally? Its just a mutated strain of the family commonly termed common cold.\nOr a laboratory enhanced version of the common cold released into the world?

So is COV19 just a new strain of the common cold family, like SARS and MERES? Boy did I laugh at this idea?\nAnd if they have never isolated the COV19, how would they know anyway?

The Stanford Children’s Health clearly explains the distinction needed to understand this false claim: "A novel coronavirus is a new coronavirus that has not been previously identified. The virus causing coronavirus disease 2019 (COVID-19), is not the same as the coronaviruses that commonly circulate among humans and cause mild illness, like the common cold.” ( here ) While it is in the family of coronaviruses, COVID-19 is a new virus affecting humans. \n\nCan anybody explain this?\n\nMy wife saw a video today that COV19 is just a new strain of the common cold?

So I would have been better off getting a 16mm copper tube, squashing the ends in a vice clamp and drilling the 21mm hole myself, would have cost less, be better understood by me, and I would have got the product much faster, without all this "hoo har" of dozens of labeling stuff that confuses people no end. The good luck understanding the hole that really matters. Called fixing hole. What a dumb name for the most important part of a cable lug.

Light experiments

@lyse You so go to have around Lyse. I going to see if a local Engineer has a 20mm bit and drill these holes straight away, otherwise, I will have to drill it myself as you say. Who would know the most important hole is called the fixing hole and the least important hole is called the stud hole. Stupid terminology, nothing is every explained/

True better to engineer things yourself, anyhow, I have to drill out these holes bigger, just because of the confusion of words over products. \n\nWhat happened to keep is simple stupid. KISS

Quote "While it is in the family of coronaviruses, COVID-19 is a new virus affecting humans"\n\nThe word "it" refers to the common cold virus.\n\nWhile"common cold virus" is in the family of coronaviruses, COVID-19 is a new virus affecting humans.\nReally? Its just a mutated strain of the family commonly termed common cold.\nOr a laboratory enhanced version of the common cold released into the world?

So is COV19 just a new strain of the common cold family, like SARS and MERES? Boy did I laugh at this idea?\nAnd if they have never isolated the COV19, how would they know anyway?

The Stanford Children’s Health clearly explains the distinction needed to understand this false claim: "A novel coronavirus is a new coronavirus that has not been previously identified. The virus causing coronavirus disease 2019 (COVID-19), is not the same as the coronaviruses that commonly circulate among humans and cause mild illness, like the common cold.” ( here ) While it is in the family of coronaviruses, COVID-19 is a new virus affecting humans. \n\nCan anybody explain this?\n\nMy wife saw a video today that COV19 is just a new strain of the common cold?

So I would have been better off getting a 16mm copper tube, squashing the ends in a vice clamp and drilling the 21mm hole myself, would have cost less, be better understood by me, and I would have got the product much faster, without all this "hoo har" of dozens of labeling stuff that confuses people no end. The good luck understanding the hole that really matters. Called fixing hole. What a dumb name for the most important part of a cable lug.

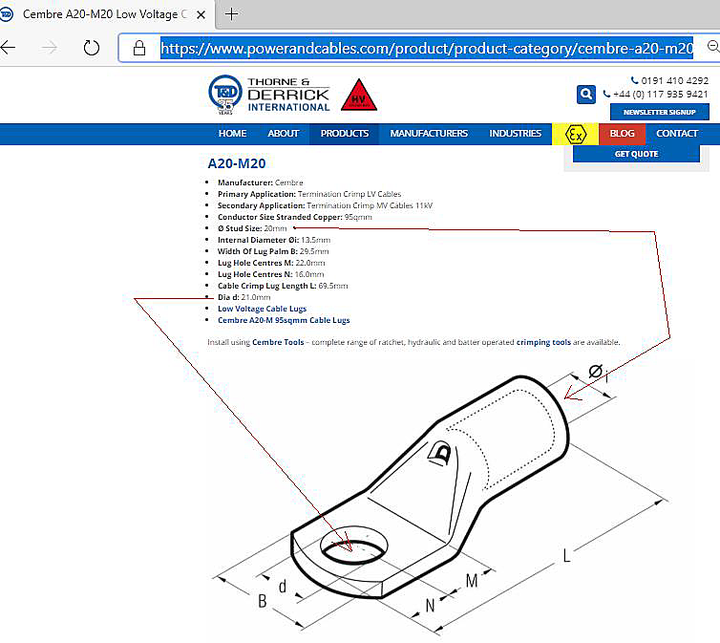

Here is what might be the proper product I want, but alas no price is displayed...so you have to enquire, BOTHER. Notice all the BIG names, STUD HOLE, etc, and unimportant to me, yet the actual diameter to fit the battery post, gets no name, just d=20mm. Weird. Stupid terminology naming things.=

Here is what might be the proper product I want, but alas no price is displayed...so you have to enquire, BOTHER. Notice all the BIG names, STUD HOLE, etc, and unimportant to me, yet the actual diameter to fit the battery post, gets no name, just d=20mm. Weird. Stupid terminology naming things.=

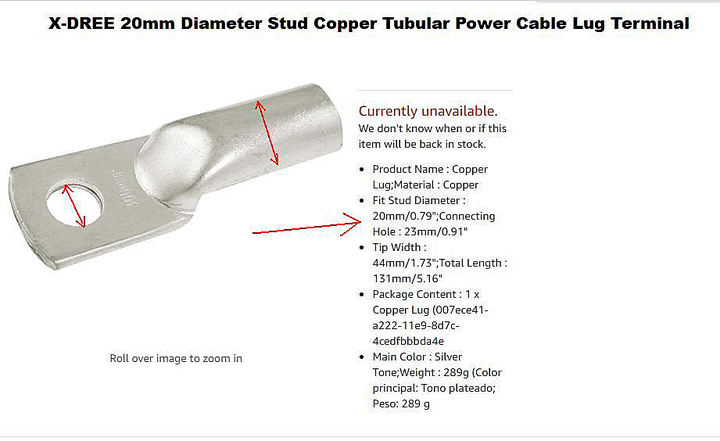

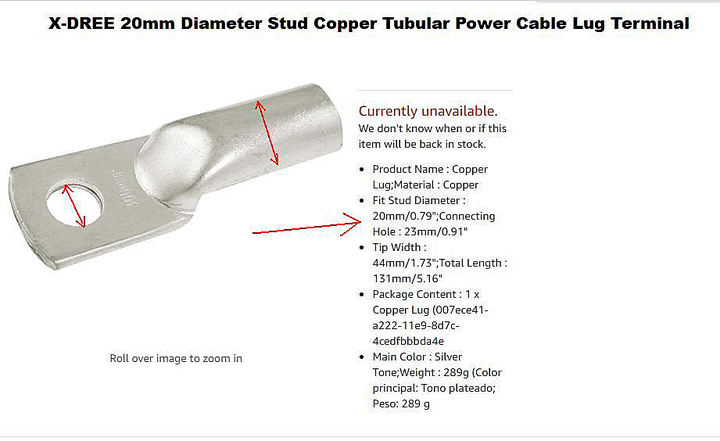

This is what I purchased, thanks to browsing history, Amazon has no records of my purchase, isn't that funny? Notice the confusing lack of words shown in red.

SO it seems I required a M20 fixing hole cable lug? Hmm?

The red arrow show the desired hole required. I will have to get somebody with a 20mm drill and drill out the hole. I found a website explaining :\n\n"Stud size is not normally of major concern as most crimp terminals or lugs would be available in a standard range of sizes that correspond to the wire size. The fixing hole sizes are commonly shown as metric (e.g. M6) or sometimes American (e.g. ¼) screw sizes. Please see the Panduit stud size chart and our own American to metric screw comparison chart.\nThe problem you may encounter is when you are using tube terminals. "

This is what I purchased, thanks to browsing history, Amazon has no records of my purchase, isn't that funny? Notice the confusing lack of words shown in red.

SO it seems I required a M20 fixing hole cable lug? Hmm?

The red arrow show the desired hole required. I will have to get somebody with a 20mm drill and drill out the hole. I found a website explaining :\n\n"Stud size is not normally of major concern as most crimp terminals or lugs would be available in a standard range of sizes that correspond to the wire size. The fixing hole sizes are commonly shown as metric (e.g. M6) or sometimes American (e.g. ¼) screw sizes. Please see the Panduit stud size chart and our own American to metric screw comparison chart.\nThe problem you may encounter is when you are using tube terminals. "

Well well, another Internet purchase mistake.\nSeems like you cannot get the terminology right and end up with the wrong product. I would have been better getting a cope pipe and making my own..\n\nIt seems 20mm stud hole refers to the end diameter of a cable lug?? This product is rated for 300mm2 cable, ie able to carry something like 1000 Amps, what too big for me/

Great news, some chicken wire has arrived from our order long ago, since than the truck rolled and destroyed our cargo. We have only 15 rolls to pick up, but we are getting there. Now I have another few projects to build.

Well well, another Internet purchase mistake.\nSeems like you cannot get the terminology right and end up with the wrong product. I would have been better getting a cope pipe and making my own..\n\nIt seems 20mm stud hole refers to the end diameter of a cable lug?? This product is rated for 300mm2 cable, ie able to carry something like 1000 Amps, what too big for me/

Great news, some chicken wire has arrived from our order long ago, since than the truck rolled and destroyed our cargo. We have only 15 rolls to pick up, but we are getting there. Now I have another few projects to build.

GOD wrote the ten descriptors of love on stone, using Hebrew words with God's own finger, that Moses is holding up here. This implies to me that that love is universal, and love rules can be written down, even though true love is beyond mere rules.

Having trouble matching the output of my Inverters, hard to find a 4.0 amp Circuit breaker, eventually found ones made in the USA for 25 each, includes freight and duty costs. Way cheaper than 80 each a shop quoted me. Not sure if I can cover or mount them, or even use them? I mean when a product says something, does this mean what they wrote is true? I have bought things before with untrue product descriptions.

@kt84 Nice cherry tomatoes.

GOD wrote the ten descriptors of love on stone, using Hebrew words with God's own finger, that Moses is holding up here. This implies to me that that love is universal, and love rules can be written down, even though true love is beyond mere rules.

Having trouble matching the output of my Inverters, hard to find a 4.0 amp Circuit breaker, eventually found ones made in the USA for 25 each, includes freight and duty costs. Way cheaper than 80 each a shop quoted me. Not sure if I can cover or mount them, or even use them? I mean when a product says something, does this mean what they wrote is true? I have bought things before with untrue product descriptions.

@kt84 Nice cherry tomatoes.

Interesting search engine. Still developing. Tried to search "solar panels", no results made sense. How does the search handle spelling mistakes? I am amazed anyone can achieve this so quickly and make something work.

Hoping the solar panels will create a tropical roof affect over the building and shade it somewhat. This frame will hold 12 solar panels, each 200 watt, giving me, using the MPPT a theoretical yield of 2400 watts. Over a 4 hour sunshine, I should get in theory 9,600 watts of power. For a 24 Volt system, this means I should get 9600/24= 400 Amp hours. Not sure of the theory verses the practical production of power, until the system is up and running.

Interesting search engine. Still developing. Tried to search "solar panels", no results made sense. How does the search handle spelling mistakes? I am amazed anyone can achieve this so quickly and make something work.

Hoping the solar panels will create a tropical roof affect over the building and shade it somewhat. This frame will hold 12 solar panels, each 200 watt, giving me, using the MPPT a theoretical yield of 2400 watts. Over a 4 hour sunshine, I should get in theory 9,600 watts of power. For a 24 Volt system, this means I should get 9600/24= 400 Amp hours. Not sure of the theory verses the practical production of power, until the system is up and running.

This view shows the 23 degree tilt towards North, to get maximum solar power from the solar panels.

This view shows the 23 degree tilt towards North, to get maximum solar power from the solar panels.

The solar panel supporting frames are bolted into place.

@prologic Complexity is the killer of all invention!\n\nHow true. Keep Inventions Simply Simple. KISS

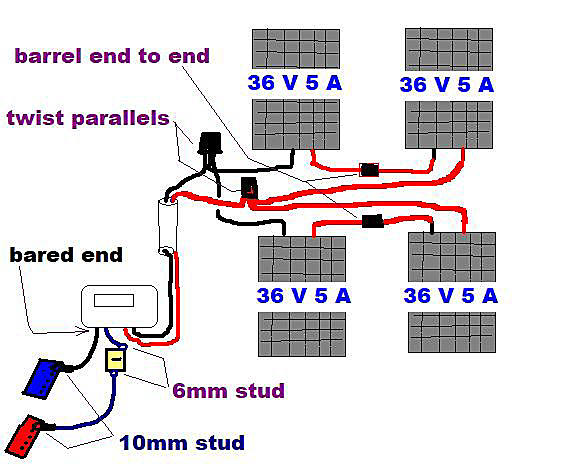

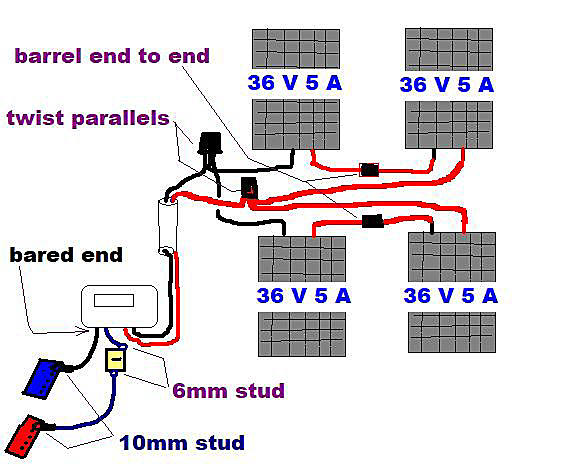

The MPPT is rated to 30 amps, so the 72 V 10A becomes 27V float at 26Amps, wasting no power, unlike the cheaper PMW controllers. This is theoretical maximums for each series and parallel solar arrays, each rated at 200Watts.

The solar panel supporting frames are bolted into place.

@prologic Complexity is the killer of all invention!\n\nHow true. Keep Inventions Simply Simple. KISS

The MPPT is rated to 30 amps, so the 72 V 10A becomes 27V float at 26Amps, wasting no power, unlike the cheaper PMW controllers. This is theoretical maximums for each series and parallel solar arrays, each rated at 200Watts.

Getting ready for details of the proposed solar strings for each MPPT solar controllers.

Getting ready for details of the proposed solar strings for each MPPT solar controllers.

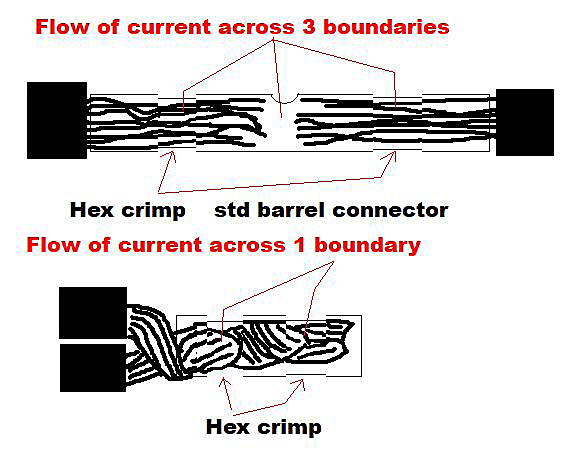

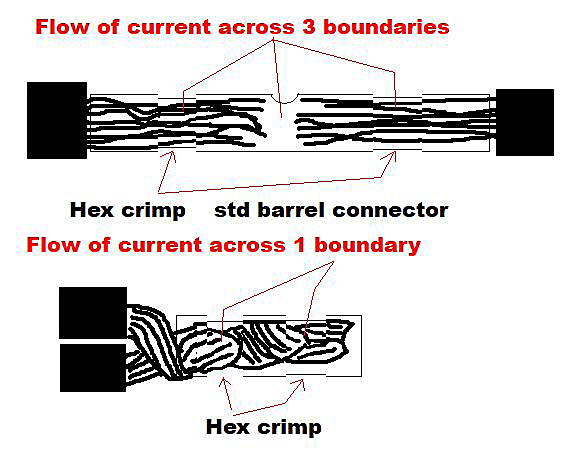

Why can't I find advice on better crimping techniques. This proposal of mine is far better, reduces potential barriers of current from 3 interfaces to one, or none. You twist the wires together as electricians already do, and use the crimp only to hold the connection, not make the connection.

I suggest people download the SPARS report for 2025 to 2028, from John Hopkins Medial University Hospital and read their potential stories of how Corona Virus Pandemic will play out for the next 7 years ahead. It is a 20MB download and 89 page report.

@prologic How true, no such thing as zero maintenance.

@lyse Maybe, have a single computer fan removing the H2S smells from pit compost toilet, a room about 1.5 by 1.0 by 1.5m and this fan works 24/7 has done for 4 years, plus AGM lead acid battery for 4 years, remarkable really. No dead battery after 4 yrs, but it daily cycles to 95% fully charged each day.\n\nI will see how this room stands up, two fans on 24/7, size 4 by 2.8 by 2.0m. \n\nCheers

Why can't I find advice on better crimping techniques. This proposal of mine is far better, reduces potential barriers of current from 3 interfaces to one, or none. You twist the wires together as electricians already do, and use the crimp only to hold the connection, not make the connection.

I suggest people download the SPARS report for 2025 to 2028, from John Hopkins Medial University Hospital and read their potential stories of how Corona Virus Pandemic will play out for the next 7 years ahead. It is a 20MB download and 89 page report.

@prologic How true, no such thing as zero maintenance.

@lyse Maybe, have a single computer fan removing the H2S smells from pit compost toilet, a room about 1.5 by 1.0 by 1.5m and this fan works 24/7 has done for 4 years, plus AGM lead acid battery for 4 years, remarkable really. No dead battery after 4 yrs, but it daily cycles to 95% fully charged each day.\n\nI will see how this room stands up, two fans on 24/7, size 4 by 2.8 by 2.0m. \n\nCheers

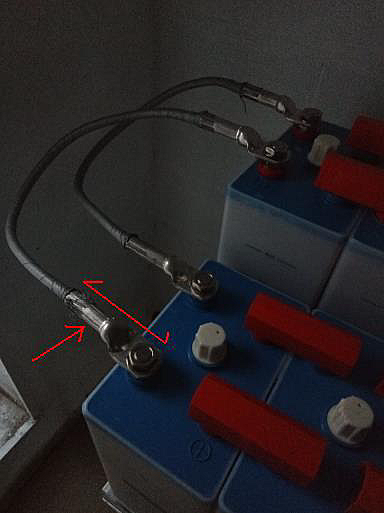

Longer view of battery bank set up. All I need now is the cable lugs on the ends, and the copper plate bus bar on the other end, and I am ready to go.

Longer view of battery bank set up. All I need now is the cable lugs on the ends, and the copper plate bus bar on the other end, and I am ready to go.

Hopefully this is hooked up OK, hard to confirm this on the Internet, as not much about Ni-Fe battery banks around. But I ran across a few images the same as mine.

Hopefully this is hooked up OK, hard to confirm this on the Internet, as not much about Ni-Fe battery banks around. But I ran across a few images the same as mine.

Cleaned the posts, spring washers and nuts.\nTightened them with shifting spanner, not too tight, just until spring washer is flat on the post.

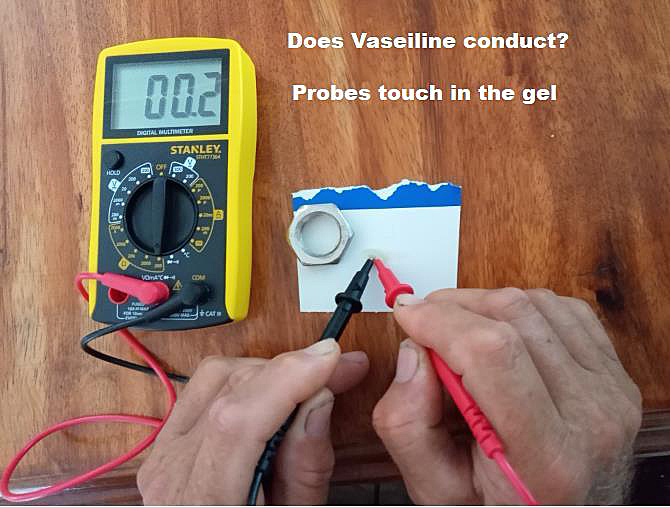

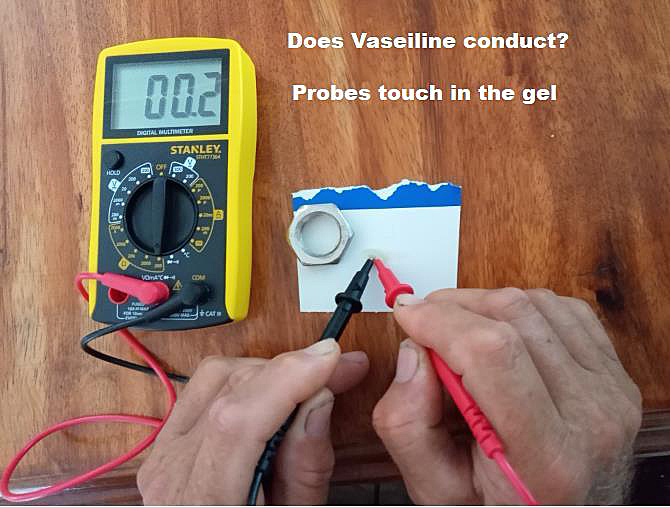

So should you use Vaseline to protect your battery terminals from corrosion? I don't. Clean your battery posts regularly, and remove cause of KOH reaching the terminals, is my answer. \n\nIt's a forum debate out there, over which is best, or better. Maintenance is the best option. \nThe AGM lead acid batteries are zero maintenance. Is this a good idea? Is there such a thing?\n\nMy personal opinion is to maintain your Nickel Iron power system, Sure it gassy, weakly corrosive and needs attention every now and than. More about this once I learn how much maintenance is needed.

Cleaned the posts, spring washers and nuts.\nTightened them with shifting spanner, not too tight, just until spring washer is flat on the post.

So should you use Vaseline to protect your battery terminals from corrosion? I don't. Clean your battery posts regularly, and remove cause of KOH reaching the terminals, is my answer. \n\nIt's a forum debate out there, over which is best, or better. Maintenance is the best option. \nThe AGM lead acid batteries are zero maintenance. Is this a good idea? Is there such a thing?\n\nMy personal opinion is to maintain your Nickel Iron power system, Sure it gassy, weakly corrosive and needs attention every now and than. More about this once I learn how much maintenance is needed.

I touch the probes inside the gel, the probes are already coated in the gel, yet by pressing the contacts together, some metal to metal surfaces get through, so the ohmmeter records near zero impedance.

I touch the probes inside the gel, the probes are already coated in the gel, yet by pressing the contacts together, some metal to metal surfaces get through, so the ohmmeter records near zero impedance.

The question is asked Does Vaseiline Petroleum Jelly conduct electricity, and useful on battery terminals? \nI use a ohmeter with probes in the gel one mm apart. Answer is no. The jelly does not conduct.

Thanks for the comments everyone. Bit worried about humidity inside the room, two computer 12V fans is series, might help remove the stale air trapped inside?

The left side lagged 2.5mm from level, but became level from counter-level principle once other right side is loaded. Both side of the cage are now near level, so the 3mm angle iron spanning 900mm is just enough to carry the weight.

Having trouble sourcing the 20mm diameter hold stud cable lugs, able to carry 200Amps., the image shows them pictured as black leads.

The question is asked Does Vaseiline Petroleum Jelly conduct electricity, and useful on battery terminals? \nI use a ohmeter with probes in the gel one mm apart. Answer is no. The jelly does not conduct.

Thanks for the comments everyone. Bit worried about humidity inside the room, two computer 12V fans is series, might help remove the stale air trapped inside?

The left side lagged 2.5mm from level, but became level from counter-level principle once other right side is loaded. Both side of the cage are now near level, so the 3mm angle iron spanning 900mm is just enough to carry the weight.

Having trouble sourcing the 20mm diameter hold stud cable lugs, able to carry 200Amps., the image shows them pictured as black leads.

The middle of the bank, turns the corner, and the leads are not black or red, technically white means 'load'; each post is wired +ve to -ve. This ensures the bank is wired +ve to -ve, but the posts are diagonally opposite, a full 3.8m away, across all 20 cells. This is the most efficient way to join to a battery bank.

The middle of the bank, turns the corner, and the leads are not black or red, technically white means 'load'; each post is wired +ve to -ve. This ensures the bank is wired +ve to -ve, but the posts are diagonally opposite, a full 3.8m away, across all 20 cells. This is the most efficient way to join to a battery bank.

The power end of the battery bank, each post is sharing the current load, so a copper plate with holes drilled for each inverter draw-off.

The power end of the battery bank, each post is sharing the current load, so a copper plate with holes drilled for each inverter draw-off.

Larger view. Note why the batteries are staged higher than the other, to view topping up with distilled water. Also note the way the batteries go, +ve to -ve posts, along the cage frame.

Larger view. Note why the batteries are staged higher than the other, to view topping up with distilled water. Also note the way the batteries go, +ve to -ve posts, along the cage frame.

Couldn't find a shop to cut sheets, so went with thin but larger angle iron. This is 30 by 30 and 1.2mm thick, fits inside the other angle iron, and allows the plastic feet of battery with support. I suggest welding from the beginning a 50 by 50 angle iron 3mm thick will solve this problem.

Also you cannot source a 20mm stud hole cable lug, only on the Internet, no shop has them. Bother. More delays.

Couldn't find a shop to cut sheets, so went with thin but larger angle iron. This is 30 by 30 and 1.2mm thick, fits inside the other angle iron, and allows the plastic feet of battery with support. I suggest welding from the beginning a 50 by 50 angle iron 3mm thick will solve this problem.

Also you cannot source a 20mm stud hole cable lug, only on the Internet, no shop has them. Bother. More delays.

I didn't know the base of the batteries have round plastic feet to stand on, and these are missing the angel iron, see red arrows. So now I need to place a steel plate into the angel iron channel to support the plastic feet of each battery. Bother you miss so many details when you build and plan, without experience.

I didn't know the base of the batteries have round plastic feet to stand on, and these are missing the angel iron, see red arrows. So now I need to place a steel plate into the angel iron channel to support the plastic feet of each battery. Bother you miss so many details when you build and plan, without experience.

Painted the power house green.

One mistake I apparently made, you cannot draw off a lower DC voltage between the cells of the 24 VDC, such as 9VDV or 12 VDV, as this causes a change to the battery bank internal resistance, interfering with solar charging. So I need a 24 V DC to DC converter, to power 18V computers, 12 V TV and 9V meters.

@lyse Probably you are right, tube steel posts used for homes do rust on the inside, but the most common oxidation is the outside, where the dew night and day temperatures react with the post going into the concrete. So there I paint them with zinc paint, and hydroseal (bitumen paint) before concreting the posts in place. Re stumping contractors do not do this, and the posts do not last.

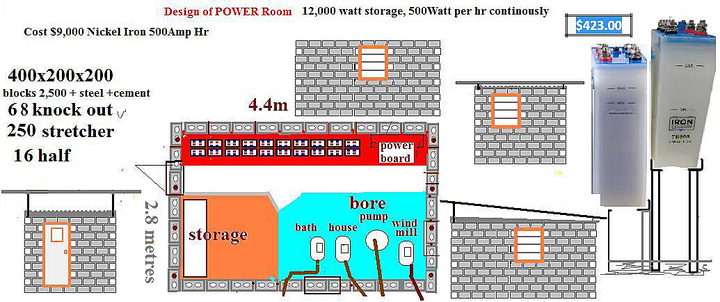

Notice four pumps, storage and power areas of the room, and even the cage frame show the staged height of each row of batteries, make it easier to top up distilled water to each battery cell.

Painted the power house green.

One mistake I apparently made, you cannot draw off a lower DC voltage between the cells of the 24 VDC, such as 9VDV or 12 VDV, as this causes a change to the battery bank internal resistance, interfering with solar charging. So I need a 24 V DC to DC converter, to power 18V computers, 12 V TV and 9V meters.

@lyse Probably you are right, tube steel posts used for homes do rust on the inside, but the most common oxidation is the outside, where the dew night and day temperatures react with the post going into the concrete. So there I paint them with zinc paint, and hydroseal (bitumen paint) before concreting the posts in place. Re stumping contractors do not do this, and the posts do not last.

Notice four pumps, storage and power areas of the room, and even the cage frame show the staged height of each row of batteries, make it easier to top up distilled water to each battery cell.

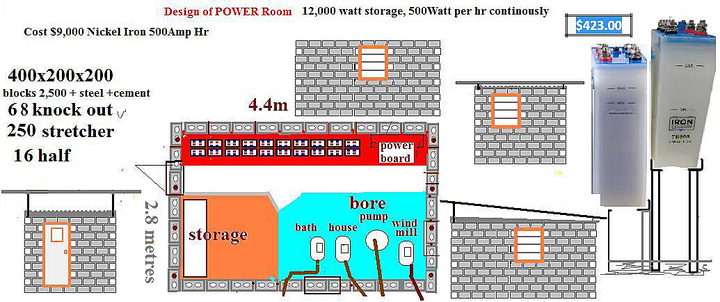

Here is the basic floor plan again the each intended use of the room.

Yes the power house has multi purpose functions. It houses our water bore, the most important thing to a property is a source of good bore water, and we finally have that. It also houses all the water pumps, around four of those. It is a storage room for spare water pumps, batteries, lights etc. And finally it houses all the battery power and 240 volt production needs.

@lyse Good point Lyse. I didn't paint the welding either, just dropped it into the concrete. Some say iron doesn't rust further once it has a coating of rust on it, but should the frame fail after 10 years of use, I guess I will have to weld up another one. The KOH electrolyte is corrosive in the batteries, and we use Vaseline to protect the battery rail connectors, so I will try to paint over the ends of the square tubing though they are welded up by the channel that sits over the top of each on.

Here is the basic floor plan again the each intended use of the room.

Yes the power house has multi purpose functions. It houses our water bore, the most important thing to a property is a source of good bore water, and we finally have that. It also houses all the water pumps, around four of those. It is a storage room for spare water pumps, batteries, lights etc. And finally it houses all the battery power and 240 volt production needs.

@lyse Good point Lyse. I didn't paint the welding either, just dropped it into the concrete. Some say iron doesn't rust further once it has a coating of rust on it, but should the frame fail after 10 years of use, I guess I will have to weld up another one. The KOH electrolyte is corrosive in the batteries, and we use Vaseline to protect the battery rail connectors, so I will try to paint over the ends of the square tubing though they are welded up by the channel that sits over the top of each on.

Side view showing the staged height difference for batteries. Hope it will hold them up, the channel is only 3mm thick, each post holds 100Kg, the spans are 900mm and must hold 100Kg per channel, I suspect a little sagging in worse case?? Overall the batteries will place 800Kg unto this frame.

Side view showing the staged height difference for batteries. Hope it will hold them up, the channel is only 3mm thick, each post holds 100Kg, the spans are 900mm and must hold 100Kg per channel, I suspect a little sagging in worse case?? Overall the batteries will place 800Kg unto this frame.

The finished weld battery cage, concreted into dirt floor.

The finished weld battery cage, concreted into dirt floor.

A close up of the welding position, note the clamp to ensure the width of channels is exactly 285mm, the width of the batteries is 280mm.

A close up of the welding position, note the clamp to ensure the width of channels is exactly 285mm, the width of the batteries is 280mm.

Began to weld channels to top of cage frame for batteries, note it is upside down, right to left, and held in place by star pickets and rope, everything level, using three spirit levels. Hard to set up, and weld by yourself.

@lyse @prologic Arr yes Lyse there is no kill like overkill. We don't have a secure storage room on our property, so this room is it.

Cost of paint and the power house is ready for the electrical batteries. Yeah.\nWill begin welding the cage frame for the batteries.

Began to weld channels to top of cage frame for batteries, note it is upside down, right to left, and held in place by star pickets and rope, everything level, using three spirit levels. Hard to set up, and weld by yourself.

@lyse @prologic Arr yes Lyse there is no kill like overkill. We don't have a secure storage room on our property, so this room is it.

Cost of paint and the power house is ready for the electrical batteries. Yeah.\nWill begin welding the cage frame for the batteries.

Also fitted the insect screen, Red arrow shows the cement render over the roof gaps, making everything insect proof.

The red arrow shows the cement render, vermin proof rafter and roof areas.

Also fitted the insect screen, Red arrow shows the cement render over the roof gaps, making everything insect proof.

The red arrow shows the cement render, vermin proof rafter and roof areas.

The door opened, with lots of steel, so you can't break in.

The door opened, with lots of steel, so you can't break in.

Finished the door today. Lots of welding all day.

@kt84 I would never a mask personally, as breathing in your own exhaust gases leads to illheath. We are supposed to breathe in 0.023% CO2, with a mask on, your breathing in 7% CO2, a massive increase in CO2 poisoning. One sign is more headaches, drowsiness and slowness of brain function. A simple Internet study reveals masks do not prevent contamination anyway.

Finished the cement rat barrier of power room, grinded off excess mortar, ready for painting. Could add steel flashing to roof, but costly, about $150, money I don't have right now. At least the power room is vermin proof, albeit a bit ugly looking.

Yes I just tried this with Lyse, and it is a nice feature. You could remove the conversation, reply feature buttons, too complex, a reply is the beginning of a conversation, a reply to a reply adds to the conservation already. Is there any difference in these buttons from a programmer end? I like to keep things simple.\nJust leave the reply feature.

I am glad you do Lyse. Soon I will show you all how to wire up the power required for off grid to run daily a house consuming 5 units of power daily. The system has a total storage of 12 units, leaving some in reserve leaves us with 10 units of power. That means we have only 2 days of power without sunshine. In Australia we can get away with this as Qld is a sunny place, no so if you are in a cloudy, snowy or wet place. You would need more batteries, more panels and maybe consume less power.

Finished the door today. Lots of welding all day.

@kt84 I would never a mask personally, as breathing in your own exhaust gases leads to illheath. We are supposed to breathe in 0.023% CO2, with a mask on, your breathing in 7% CO2, a massive increase in CO2 poisoning. One sign is more headaches, drowsiness and slowness of brain function. A simple Internet study reveals masks do not prevent contamination anyway.

Finished the cement rat barrier of power room, grinded off excess mortar, ready for painting. Could add steel flashing to roof, but costly, about $150, money I don't have right now. At least the power room is vermin proof, albeit a bit ugly looking.

Yes I just tried this with Lyse, and it is a nice feature. You could remove the conversation, reply feature buttons, too complex, a reply is the beginning of a conversation, a reply to a reply adds to the conservation already. Is there any difference in these buttons from a programmer end? I like to keep things simple.\nJust leave the reply feature.

I am glad you do Lyse. Soon I will show you all how to wire up the power required for off grid to run daily a house consuming 5 units of power daily. The system has a total storage of 12 units, leaving some in reserve leaves us with 10 units of power. That means we have only 2 days of power without sunshine. In Australia we can get away with this as Qld is a sunny place, no so if you are in a cloudy, snowy or wet place. You would need more batteries, more panels and maybe consume less power.

Finally I have to cement the surrounds to make everything rat and mouse proof. Notice the chicken wire for a background support for the cement render.

Finally I have to cement the surrounds to make everything rat and mouse proof. Notice the chicken wire for a background support for the cement render.

View of roof, most sheets are second hand, as the rafters and purlins were also. I started with a 100x50 on its side, than a 75 by 75, than a 100x50, than finally a 100 x 50 on its side with a 100 x 50 upright, the last two beams are bolted together. This is a low fall of 50, 75, 100, and 150mm over a distance of 4m. Or 100mm over 4m.

View of roof, most sheets are second hand, as the rafters and purlins were also. I started with a 100x50 on its side, than a 75 by 75, than a 100x50, than finally a 100 x 50 on its side with a 100 x 50 upright, the last two beams are bolted together. This is a low fall of 50, 75, 100, and 150mm over a distance of 4m. Or 100mm over 4m.

The roof and ceiling are in place, and the 23 degree angle support for solar panels are bolted to a threaded 12mm rod running down into the building.

Lots of rain over here. Water across roads. Lots of mozzies too. However it's a blessing, the garden trees will grow better on fresh than bore water.

What a long week on my own, working as a gardener. It's a wonderful object lesson. Last day today. Yeah.

Bit wet today, long day too. Having a look at the best MPPT solar controller, the Victron 100 Volt, 30 Amp. This takes in 72 volt panels at 5 amps and converts to 27 volts at 26 amps. They are roughly $200 each and have adjustable voltage float settings for different kinds of batteries. That is important.

The roof and ceiling are in place, and the 23 degree angle support for solar panels are bolted to a threaded 12mm rod running down into the building.

Lots of rain over here. Water across roads. Lots of mozzies too. However it's a blessing, the garden trees will grow better on fresh than bore water.

What a long week on my own, working as a gardener. It's a wonderful object lesson. Last day today. Yeah.

Bit wet today, long day too. Having a look at the best MPPT solar controller, the Victron 100 Volt, 30 Amp. This takes in 72 volt panels at 5 amps and converts to 27 volts at 26 amps. They are roughly $200 each and have adjustable voltage float settings for different kinds of batteries. That is important.

Hot day today, exhausting mowing grass with all this wet weather about.

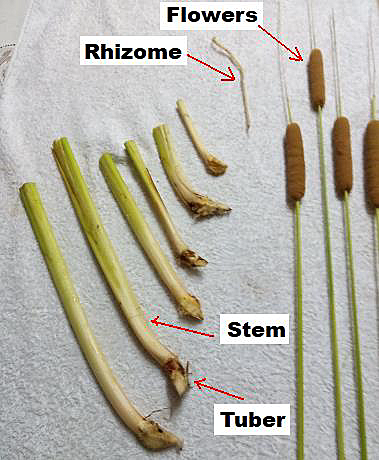

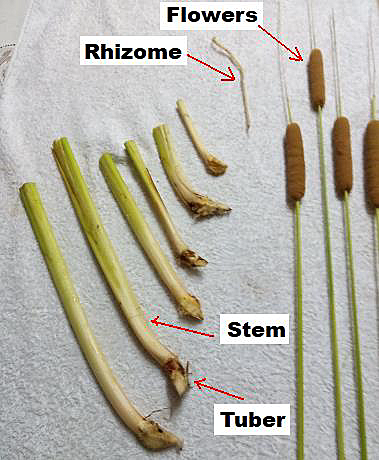

Have lots to learn about cumbungi, you need a crowbar or fork to dig it up, what I obtained was wrong....and roasted it is nice as Aborigines and Pioneers say

Hot day today, exhausting mowing grass with all this wet weather about.

Have lots to learn about cumbungi, you need a crowbar or fork to dig it up, what I obtained was wrong....and roasted it is nice as Aborigines and Pioneers say

Cumbungi looks like this, after roughly prepared for eating, washed etc. And they call this a staple? I don't think so. Would lose weight eating this everyday for a whole week/LOL. I will cook this up and let you know.

Happy 2021 everyone.\nTo my mum and my wife :)

Cumbungi looks like this, after roughly prepared for eating, washed etc. And they call this a staple? I don't think so. Would lose weight eating this everyday for a whole week/LOL. I will cook this up and let you know.

Happy 2021 everyone.\nTo my mum and my wife :)

My gif image\n\nWhy doesn't the image appear as gif, ie animated?

My gif image\n\nWhy doesn't the image appear as gif, ie animated?

Hard work

Hard work

Does this work here?

I think I am back, my telstra bungle allowed me on, despite no account details, and this is windows 10, microsoft edge. On Lenovo, cost me $200, second hand.

rained yesterday, preventing me from finishing my work

Does this work here?

I think I am back, my telstra bungle allowed me on, despite no account details, and this is windows 10, microsoft edge. On Lenovo, cost me $200, second hand.

rained yesterday, preventing me from finishing my work

The window end of the power room. Notice the blocks are used to make string line supports.

I mix only 1 cement and 3 sand each time, not much, but on hot days, the cement goes off fast, so add little water half way through and mix again to creamy texture. Cover you barrow with cloth helps keep sun off.

The window end of the power room. Notice the blocks are used to make string line supports.

I mix only 1 cement and 3 sand each time, not much, but on hot days, the cement goes off fast, so add little water half way through and mix again to creamy texture. Cover you barrow with cloth helps keep sun off.

Make your mortar go past each block you lay, so it has time to go off, and hold up the block once it is placed. Than point up your work with your trowel, adding mortar to missing joints and filling in gaps, pressing the point of the trowel so you get strong adhesive forces within the mortar.

Make your mortar go past each block you lay, so it has time to go off, and hold up the block once it is placed. Than point up your work with your trowel, adding mortar to missing joints and filling in gaps, pressing the point of the trowel so you get strong adhesive forces within the mortar.

Welded window frame, red circle, notice 4 courses left to top of door and window, but 10mm is not enough, making 20 mm short, so I need each mortar layer to be 15mm thick. See red arrows.

Welded window frame, red circle, notice 4 courses left to top of door and window, but 10mm is not enough, making 20 mm short, so I need each mortar layer to be 15mm thick. See red arrows.

Progress, Laid about 32 blocks today, including doing all the tasks myself. Getting blocks, pointing up grooves, raking, and mixing cement. I use a strong brew, 1 cement to 3 sand, as my sand is bush sand, and has some mud in it. Make small patches as it goes off fast on a hot day.

Progress, Laid about 32 blocks today, including doing all the tasks myself. Getting blocks, pointing up grooves, raking, and mixing cement. I use a strong brew, 1 cement to 3 sand, as my sand is bush sand, and has some mud in it. Make small patches as it goes off fast on a hot day.

The mortar must be 10mm tick, so I use a thick tile (red arrow) to make level for string line to follow. Laying blocks with a string line is easiest way.

The mortar must be 10mm tick, so I use a thick tile (red arrow) to make level for string line to follow. Laying blocks with a string line is easiest way.

The copper rail bar, drilled to share the two battery posts, and nine 10mm brass bolts for adding power in or out.

The copper rail bar, drilled to share the two battery posts, and nine 10mm brass bolts for adding power in or out.

A rough, unpainted steel supporting frame for all the 18 battery cable wires leading from copper rail plate, pictured in orange, to the black wall. One wire shown in red.

A rough, unpainted steel supporting frame for all the 18 battery cable wires leading from copper rail plate, pictured in orange, to the black wall. One wire shown in red.

A closer view showing the original lug, and the processed crimped lug.

A closer view showing the original lug, and the processed crimped lug.

Finally the crimping company I found "Pirtek" in Blackwater was able to crimp these lugs, for just $22 using a machine able to crimp up to 30,000 tonnes of force, makes my crimping tool of 12 tonnes silly

Finally the crimping company I found "Pirtek" in Blackwater was able to crimp these lugs, for just $22 using a machine able to crimp up to 30,000 tonnes of force, makes my crimping tool of 12 tonnes silly

Light experiments

Light experiments

Here is what might be the proper product I want, but alas no price is displayed...so you have to enquire, BOTHER. Notice all the BIG names, STUD HOLE, etc, and unimportant to me, yet the actual diameter to fit the battery post, gets no name, just d=20mm. Weird. Stupid terminology naming things.=

Here is what might be the proper product I want, but alas no price is displayed...so you have to enquire, BOTHER. Notice all the BIG names, STUD HOLE, etc, and unimportant to me, yet the actual diameter to fit the battery post, gets no name, just d=20mm. Weird. Stupid terminology naming things.=

This is what I purchased, thanks to browsing history, Amazon has no records of my purchase, isn't that funny? Notice the confusing lack of words shown in red.

This is what I purchased, thanks to browsing history, Amazon has no records of my purchase, isn't that funny? Notice the confusing lack of words shown in red.

Well well, another Internet purchase mistake.\nSeems like you cannot get the terminology right and end up with the wrong product. I would have been better getting a cope pipe and making my own..\n\nIt seems 20mm stud hole refers to the end diameter of a cable lug?? This product is rated for 300mm2 cable, ie able to carry something like 1000 Amps, what too big for me/

Well well, another Internet purchase mistake.\nSeems like you cannot get the terminology right and end up with the wrong product. I would have been better getting a cope pipe and making my own..\n\nIt seems 20mm stud hole refers to the end diameter of a cable lug?? This product is rated for 300mm2 cable, ie able to carry something like 1000 Amps, what too big for me/

GOD wrote the ten descriptors of love on stone, using Hebrew words with God's own finger, that Moses is holding up here. This implies to me that that love is universal, and love rules can be written down, even though true love is beyond mere rules.

GOD wrote the ten descriptors of love on stone, using Hebrew words with God's own finger, that Moses is holding up here. This implies to me that that love is universal, and love rules can be written down, even though true love is beyond mere rules.

Interesting search engine. Still developing. Tried to search "solar panels", no results made sense. How does the search handle spelling mistakes? I am amazed anyone can achieve this so quickly and make something work.

Interesting search engine. Still developing. Tried to search "solar panels", no results made sense. How does the search handle spelling mistakes? I am amazed anyone can achieve this so quickly and make something work.

This view shows the 23 degree tilt towards North, to get maximum solar power from the solar panels.

This view shows the 23 degree tilt towards North, to get maximum solar power from the solar panels.

The solar panel supporting frames are bolted into place.

The solar panel supporting frames are bolted into place.

Getting ready for details of the proposed solar strings for each MPPT solar controllers.

Getting ready for details of the proposed solar strings for each MPPT solar controllers.

Why can't I find advice on better crimping techniques. This proposal of mine is far better, reduces potential barriers of current from 3 interfaces to one, or none. You twist the wires together as electricians already do, and use the crimp only to hold the connection, not make the connection.

Why can't I find advice on better crimping techniques. This proposal of mine is far better, reduces potential barriers of current from 3 interfaces to one, or none. You twist the wires together as electricians already do, and use the crimp only to hold the connection, not make the connection.

Longer view of battery bank set up. All I need now is the cable lugs on the ends, and the copper plate bus bar on the other end, and I am ready to go.

Longer view of battery bank set up. All I need now is the cable lugs on the ends, and the copper plate bus bar on the other end, and I am ready to go.

Hopefully this is hooked up OK, hard to confirm this on the Internet, as not much about Ni-Fe battery banks around. But I ran across a few images the same as mine.

Hopefully this is hooked up OK, hard to confirm this on the Internet, as not much about Ni-Fe battery banks around. But I ran across a few images the same as mine.

Cleaned the posts, spring washers and nuts.\nTightened them with shifting spanner, not too tight, just until spring washer is flat on the post.

Cleaned the posts, spring washers and nuts.\nTightened them with shifting spanner, not too tight, just until spring washer is flat on the post.

I touch the probes inside the gel, the probes are already coated in the gel, yet by pressing the contacts together, some metal to metal surfaces get through, so the ohmmeter records near zero impedance.

I touch the probes inside the gel, the probes are already coated in the gel, yet by pressing the contacts together, some metal to metal surfaces get through, so the ohmmeter records near zero impedance.

The question is asked Does Vaseiline Petroleum Jelly conduct electricity, and useful on battery terminals? \nI use a ohmeter with probes in the gel one mm apart. Answer is no. The jelly does not conduct.

The question is asked Does Vaseiline Petroleum Jelly conduct electricity, and useful on battery terminals? \nI use a ohmeter with probes in the gel one mm apart. Answer is no. The jelly does not conduct.

The middle of the bank, turns the corner, and the leads are not black or red, technically white means 'load'; each post is wired +ve to -ve. This ensures the bank is wired +ve to -ve, but the posts are diagonally opposite, a full 3.8m away, across all 20 cells. This is the most efficient way to join to a battery bank.

The middle of the bank, turns the corner, and the leads are not black or red, technically white means 'load'; each post is wired +ve to -ve. This ensures the bank is wired +ve to -ve, but the posts are diagonally opposite, a full 3.8m away, across all 20 cells. This is the most efficient way to join to a battery bank.

The power end of the battery bank, each post is sharing the current load, so a copper plate with holes drilled for each inverter draw-off.

The power end of the battery bank, each post is sharing the current load, so a copper plate with holes drilled for each inverter draw-off.

Larger view. Note why the batteries are staged higher than the other, to view topping up with distilled water. Also note the way the batteries go, +ve to -ve posts, along the cage frame.

Larger view. Note why the batteries are staged higher than the other, to view topping up with distilled water. Also note the way the batteries go, +ve to -ve posts, along the cage frame.

Couldn't find a shop to cut sheets, so went with thin but larger angle iron. This is 30 by 30 and 1.2mm thick, fits inside the other angle iron, and allows the plastic feet of battery with support. I suggest welding from the beginning a 50 by 50 angle iron 3mm thick will solve this problem.

Couldn't find a shop to cut sheets, so went with thin but larger angle iron. This is 30 by 30 and 1.2mm thick, fits inside the other angle iron, and allows the plastic feet of battery with support. I suggest welding from the beginning a 50 by 50 angle iron 3mm thick will solve this problem.

I didn't know the base of the batteries have round plastic feet to stand on, and these are missing the angel iron, see red arrows. So now I need to place a steel plate into the angel iron channel to support the plastic feet of each battery. Bother you miss so many details when you build and plan, without experience.

I didn't know the base of the batteries have round plastic feet to stand on, and these are missing the angel iron, see red arrows. So now I need to place a steel plate into the angel iron channel to support the plastic feet of each battery. Bother you miss so many details when you build and plan, without experience.

Painted the power house green.

Painted the power house green.

Here is the basic floor plan again the each intended use of the room.

Here is the basic floor plan again the each intended use of the room.

Side view showing the staged height difference for batteries. Hope it will hold them up, the channel is only 3mm thick, each post holds 100Kg, the spans are 900mm and must hold 100Kg per channel, I suspect a little sagging in worse case?? Overall the batteries will place 800Kg unto this frame.

Side view showing the staged height difference for batteries. Hope it will hold them up, the channel is only 3mm thick, each post holds 100Kg, the spans are 900mm and must hold 100Kg per channel, I suspect a little sagging in worse case?? Overall the batteries will place 800Kg unto this frame.

The finished weld battery cage, concreted into dirt floor.

The finished weld battery cage, concreted into dirt floor.

A close up of the welding position, note the clamp to ensure the width of channels is exactly 285mm, the width of the batteries is 280mm.

A close up of the welding position, note the clamp to ensure the width of channels is exactly 285mm, the width of the batteries is 280mm.

Began to weld channels to top of cage frame for batteries, note it is upside down, right to left, and held in place by star pickets and rope, everything level, using three spirit levels. Hard to set up, and weld by yourself.

Began to weld channels to top of cage frame for batteries, note it is upside down, right to left, and held in place by star pickets and rope, everything level, using three spirit levels. Hard to set up, and weld by yourself.

Also fitted the insect screen, Red arrow shows the cement render over the roof gaps, making everything insect proof.

Also fitted the insect screen, Red arrow shows the cement render over the roof gaps, making everything insect proof.

The door opened, with lots of steel, so you can't break in.

The door opened, with lots of steel, so you can't break in.

Finished the door today. Lots of welding all day.

Finished the door today. Lots of welding all day.

Finally I have to cement the surrounds to make everything rat and mouse proof. Notice the chicken wire for a background support for the cement render.

Finally I have to cement the surrounds to make everything rat and mouse proof. Notice the chicken wire for a background support for the cement render.

View of roof, most sheets are second hand, as the rafters and purlins were also. I started with a 100x50 on its side, than a 75 by 75, than a 100x50, than finally a 100 x 50 on its side with a 100 x 50 upright, the last two beams are bolted together. This is a low fall of 50, 75, 100, and 150mm over a distance of 4m. Or 100mm over 4m.

View of roof, most sheets are second hand, as the rafters and purlins were also. I started with a 100x50 on its side, than a 75 by 75, than a 100x50, than finally a 100 x 50 on its side with a 100 x 50 upright, the last two beams are bolted together. This is a low fall of 50, 75, 100, and 150mm over a distance of 4m. Or 100mm over 4m.

The roof and ceiling are in place, and the 23 degree angle support for solar panels are bolted to a threaded 12mm rod running down into the building.

The roof and ceiling are in place, and the 23 degree angle support for solar panels are bolted to a threaded 12mm rod running down into the building.

Hot day today, exhausting mowing grass with all this wet weather about.

Hot day today, exhausting mowing grass with all this wet weather about.

Cumbungi looks like this, after roughly prepared for eating, washed etc. And they call this a staple? I don't think so. Would lose weight eating this everyday for a whole week/LOL. I will cook this up and let you know.

Cumbungi looks like this, after roughly prepared for eating, washed etc. And they call this a staple? I don't think so. Would lose weight eating this everyday for a whole week/LOL. I will cook this up and let you know.

My gif image\n\nWhy doesn't the image appear as gif, ie animated?

My gif image\n\nWhy doesn't the image appear as gif, ie animated?

Hard work

Hard work

Does this work here?

Does this work here?

The window end of the power room. Notice the blocks are used to make string line supports.

The window end of the power room. Notice the blocks are used to make string line supports.

Make your mortar go past each block you lay, so it has time to go off, and hold up the block once it is placed. Than point up your work with your trowel, adding mortar to missing joints and filling in gaps, pressing the point of the trowel so you get strong adhesive forces within the mortar.

Make your mortar go past each block you lay, so it has time to go off, and hold up the block once it is placed. Than point up your work with your trowel, adding mortar to missing joints and filling in gaps, pressing the point of the trowel so you get strong adhesive forces within the mortar.

Welded window frame, red circle, notice 4 courses left to top of door and window, but 10mm is not enough, making 20 mm short, so I need each mortar layer to be 15mm thick. See red arrows.

Welded window frame, red circle, notice 4 courses left to top of door and window, but 10mm is not enough, making 20 mm short, so I need each mortar layer to be 15mm thick. See red arrows.

Progress, Laid about 32 blocks today, including doing all the tasks myself. Getting blocks, pointing up grooves, raking, and mixing cement. I use a strong brew, 1 cement to 3 sand, as my sand is bush sand, and has some mud in it. Make small patches as it goes off fast on a hot day.

Progress, Laid about 32 blocks today, including doing all the tasks myself. Getting blocks, pointing up grooves, raking, and mixing cement. I use a strong brew, 1 cement to 3 sand, as my sand is bush sand, and has some mud in it. Make small patches as it goes off fast on a hot day.

The mortar must be 10mm tick, so I use a thick tile (red arrow) to make level for string line to follow. Laying blocks with a string line is easiest way.

The mortar must be 10mm tick, so I use a thick tile (red arrow) to make level for string line to follow. Laying blocks with a string line is easiest way.